Experiment No 9 Determination of geometry and dimensions of given composite object / single point tool, using profile projector and tool maker’s microscope.

Experiment No. 9

Title: -Experiment on tool maker’s microscope

Aim :-Study and Application of Tool Maker's Microscope.

Apparatus :-Tool maker’s microscope, specimen.

Theory: -

Introduction:- The tool maker’s microscope is a versatile instrument that measure by optical means with no pressure being involved, thus very useful for measurement on small and delicate parts. It is designed for:

a) Measurement on parts of complex form e.g. - profile of external thread, tool, templates, gauges, etc.

b) Measuring center to center distance of holes in any plane.

c) A variety of linear measurements.

d) Accurate angular measurements.

[1]

[1]

Use of Tool Makers microscope for screw thread parameter measurement.

Please see the video animation for working of all the parts of Tool Maker's Microscope

Tool maker’s microscope is shown in fig. The optical head can be moved up or down the vertical column and can be clamped at any height by means of clamping screw. The table which is mounted on the base of the instrument can be moved in two mutually perpendicular horizontal directions (longitudinal and lateral) by means of accurate micrometer screw having thimble scale and venires.

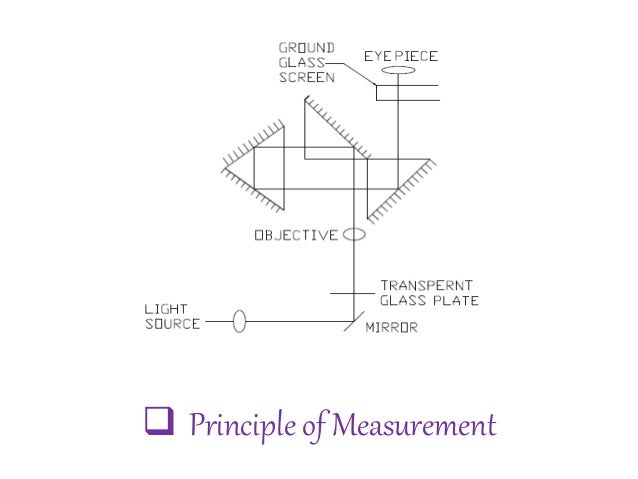

Principle of measurement: -

[2]

[2]

A ray of light from a light source fig. b is reflected by a mirror through 90’ It then passes through a transparent glass plate (on which flat parts may be placed ). A shadow image of the outline or counter of the works peaces passes through the objective of the optical head and is projected by a system of three prisms to a ground glass screen. Observations are made through an eyepiece. Measurements are made by means of cross lines engraved on the ground glass screen. The screen can be rotated through 360’; the angle of rotation is read through an auxiliary eyepiece.

Procedure: -

A) Pitch Measurement: -

1) Take the hacksaw blade and mount on the moving blade of tool maker’s Microscope in horizontal position.

2) Focus the microscope on the blade.

3) Make the cross line in the microscope coincided with one of the edge of the blade.

4) Take a reading on ground glass screen, this is the initial reading.

5) The table is again moved until the next edge of the blade coincides with the cross-line on the screen and the final reading takes.

6) The difference between initial and final reading gives pitch of the blade.

B) Teeth Angle :-

1) Place the blade on the table in same position.

2) Rotate the screen until a line on the angle of screen rotation is noted.

3) Take the angular reading, the initial one.

4) Again rotate the screen until the same line coincides with the other flank of the tooth.

5) Take the final angular reading.

6) The teeth angle of blade in the difference between the two angular readings.

Please see the video for measurement of screw thread

Observation Table:-

|

Parameter For Measurement |

Sr No. |

Initial reading |

Final reading |

Difference |

Mean |

|

Pitch |

1 |

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

Major Diameter of the Thread |

1 |

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

Minor Diameter of the Thread |

1 |

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

Thread Angle |

1 |

|

|

|

|

|

2 |

|

|

|

|

|

|

3 |

|

|

|

|

[3]

[3]

Result:-

A) Pitch of Thread =

B) Major Diameter of the Thread =

C) Minor Diameter of the Thread =

B) Thread angle =

Reference :-

1.https://www.google.com/url?sa=i&url=http%3A%2F%2Fengineeringdev.blogspot.com%2F2015%2F12%2Fautocollimator-and-tool-makers-micro.html&psig=AOvVaw22GPcFimpQhZuv1NoaJpU8&ust=1597304598454000&source=images&cd=vfe&ved=0CAIQjRxqFwoTCMi9pqGWlesCFQAAAAAdAAAAABAD

2.https://www.google.com/url?sa=i&url=https%3A%2F%2Fwww.slideshare.net%2Furveshprajapati3990%2Ftool-makers-microscope-45016114&psig=AOvVaw1h9Vj2g2YSaJL1vghFvsWE&ust=1597304711933000&source=images&cd=vfe&ved=0CAIQjRxqFwoTCNDqyeuVlesCFQAAAAAdAAAAABAD

3.https://www.google.com/url?sa=i&url=https%3A%2F%2Fwww.philholdenfasteners.co.uk%2Fevolution-screw-threads%2F&psig=AOvVaw1xv2vDekyaIg3nWOVNOYBu&ust=1597305210315000&source=images&cd=vfe&ved=0CAIQjRxqFwoTCJCZ_-OXlesCFQAAAAAdAAAAABAD

Comments

Post a Comment