EXPERIMENT NO 5 Measurement of spur gear parameters using Gear Tooth Vernier / Span Micrometer / Gear Rolling Tester

EXPERIMENT NO 5

TITLE: Measurement of gear tooth thickness by gear tooth Vernier Caliper/Constant Chord/Spam micrometer.

APPARATUS:

Gear tooth vernier caliper, vernier caliper 12’’ 300 mm, bench vice.

THEORY:

Brief description of different characteristics of measuring of tooth thickness by gear truth vernier is given. It consists of a horizontal and a vertical vernier scale. It is based on the principle of vernier scale. The thickness of a tooth at pitch line and the addendum is measured by an independent tongue each of which is adjusted independently by adjusting the slide screws on graduated beams.

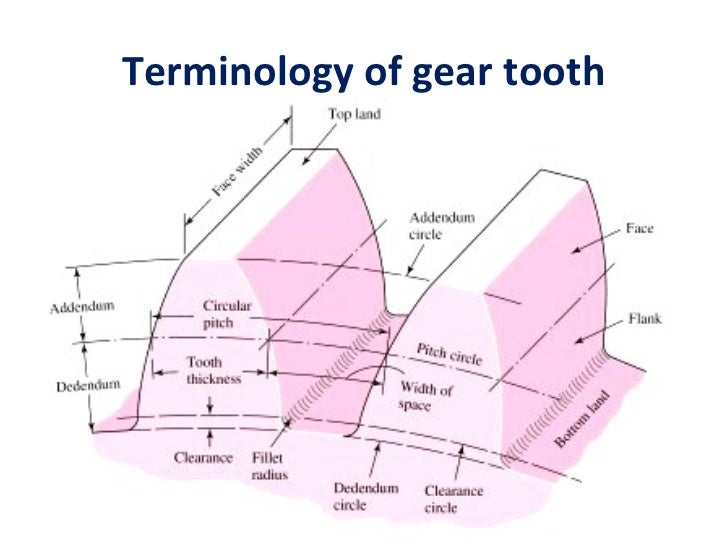

TERMINOLOGY OF GEAR TOOTH

(i) Pitch circle diameter (PCD) : It is the diameter of a circle which by pure rolling action would produce the same motion on the toothed gear wheel.

It is equal to D = (T X OD)/(T+2)OD = outside diameter T = number of teeth

(ii) MODULE: It is defined as the length of the pitch circle diameter per truth. Module m=D/T and is expressed ih mm.

(iii) CIRCULAR PITCH (CP) : It is the arc distance measured around the pitch circle from the flank of one truth to a similar flank in the next 1.00th CP==ΠD/T=Πm.

(iv) ADDENDUM: This is the radial distance from the pitch circle to the tip of the truth. It is equal to one module.

(v) Clearance: This is the radial distance from the tip of a tooth to the bottom of the mating tooth space when the teeth are symmetrically engaged. Its standard value is 0.157m or 0.25m.

(vi) DEDENDUM: This is the radial distance from the pitch circle to the bottom of tooth space.Dedendum = Addendum +Clearance = m +0.157m =1 .157m.=1.25m (metric gearing system)

ii) TOOTH THICKNESS: This is the arc distance measured along the pitch from the intercepts with one flank to the intercepts with the other flank of the same tooth.

[1]

[1]

[2]

[2]

Please see the video for working of Gear Tooth Vernier Caliper

PROCEDURE:

For finding PCD, module, addendum, dedendum and clearance:

1. First find the blank diameter, OD by a vernier caliper and also count the number of teeth T of the spur gear.

2. Next calculate pitch circle diameter D=(TxOD)/(T+2)

3. Find addendum, clearance, pitch, module and dedendum as per the formulae given in the theory.

FOR CHORDAL TOOTH THICKNESS (using gear tooth calliper):

1. Set the chordal depth (addendum) on the vertical slide of the gear tooth vernier and then insert the jaws of the instrument on the tooth to be measured.

2. Adjust the horizontal vernier slide by the fine adjusting screw so that the jaws just touch the tooth.

3. Read the horizontal vernier slide and note the reading. It gives the chordal thickness of tooth.

4. Repeat the observations for the different teeth.

5. Compare the values of different characteristics with the standard value and set the percentage error.

OBSERVATION:

1. Least count of caliper= 0.02mm

2. Number of teeth= 40

TABLE FOR SETTING GEAR TOOTH CALLIPER FOR SPUR GEAR

|

NO. OF TEETH |

30 |

32 |

34 |

36 |

38 |

40 |

42 |

|

CHORDAL THICKNESS |

1.5700 |

1.5701 |

1.5702 |

1.5703 |

1.5703 |

1.5704 |

1.5704 |

|

HEIGHT OF TOOTH |

1.0206 |

1.0192 |

1.0182 |

1.0171 |

1.0162 |

1.0154 |

1.0146 |

CHORDAL THICKNESS:

|

S NO |

M.S.R |

V.S.R |

CHORDAL THICKNESS (M.S.R+V.S.R*L.C) |

VERIFICATION (DIGITAL VERNIER CALIPER) |

|

1. |

4 |

8 |

4 + 8*0.02 = 4.16 |

4.49 |

|

2. |

4 |

9 |

4 + 9*0.02 = 4.18 |

4.32 |

HEIGHT OF THE TOOTH:

|

S NO |

M.S.R |

V.S.R |

CHORDAL THICKNESS (M.S.R+V.S.R*L.C) |

VERIFICATION (DIGITAL VERNIER CALIPER) |

|

1. |

4 |

7 |

4 + 7*0.02 = 4.14 |

4.26 |

|

2. |

4 |

6 |

4 + 6*0.02 =4.12 |

4.10 |

CALCULATIONS:

1. Pitch circle diameter, D=(TxOD)/(T+2)=

2. module, m=D/T mm=

3. Addendum=m=

4. Dedendum=m+0.157m=

CONCLUSION:

Hence we have various gear parameters of gear using vernier gear caliper.

Reference:

1. https://topmetrology.ro/2583-thickbox_default/subler-cu-vernier-0-300-mm-helios-preisser-model-0184.jpg

2. https://image.slidesharecdn.com/gearthread-120918023938-phpapp01/95/gear-thread-3-728.jpg?cb=1347939177

Comments

Post a Comment